- Home

- >

- Products

- >

- Paper Pouring Tube

- >

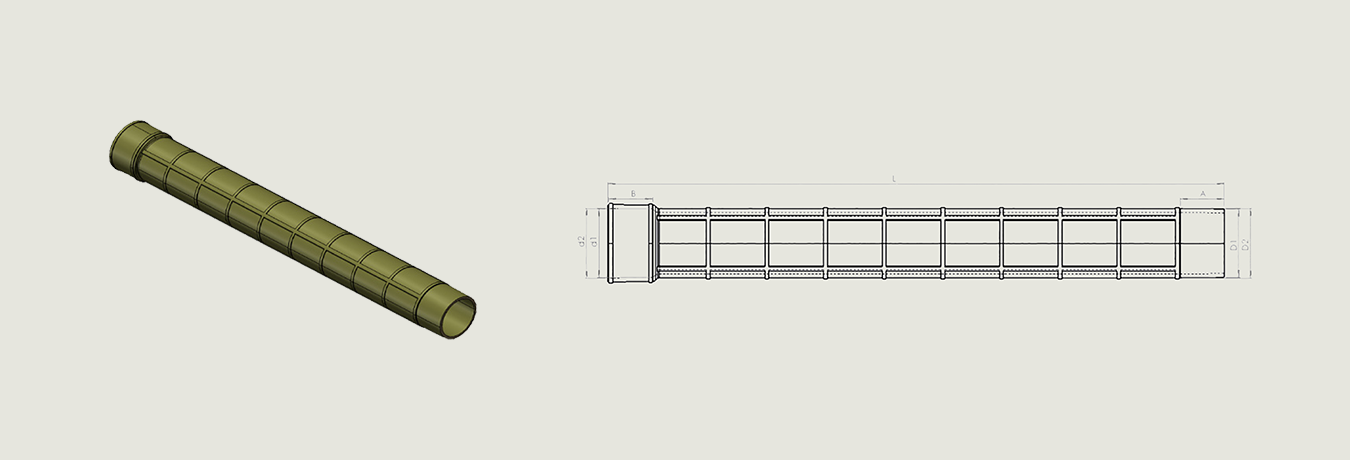

Paper Pouring Tube

Paper pouring tube for foundry can replace ceramic pouring tube, are mainly used in lost foam casting, full mold casting, traditional sand casting, etc, which can improve the quality of castings, reduce the scrap rate, improve the quality of reclaimed sand, and reduce the work intensity of workers.

- Information

Paper Pouring Tube

From aviation toautomotive manufacturing, this product delivers superiorperformance and efficiency.

Aviation: High-quality, lightweight castings for aircraft components such as brackets, frames, and engine parts.

Automobiles: Advanced metal casting technologies for automotive engine components.

Railways: Durable castings for railway machinery components, including axles, wheels, and frames.

Wind Power: Precision castings for rotating wind turbine parts, such as blades and hubs.

Our advantage

Lightweight & Durable for Operational Efficiency

Lightweight yet durable, it simplifies handling and installation, directly cutting labor costs while boosting overall operational productivity.

Waste Reduction & Simplified Cleanup

Leaves minimal residue after use, streamlining post-casting cleanup procedures. It further lowers waste disposal costs, supporting more efficient and cost-effective workshop operations.

Sustainable & Eco-Friendly by Design

Crafted from recycled pulp, it reduces waste generation and minimizes heat loss during casting processes—aligning perfectly with green manufacturing goals.

Optimal Thermal Insulation Performance

Offers excellent heat retention capabilities, which not only improves casting quality and extends the service life of related components but also reduces material waste caused by temperature inconsistencies.

Enhanced Casting Quality & Precision

Optimizes molten metal flow, significantly minimizing non-metallic inclusions in castings. This also reduces the need for post-production treatments, resulting in cleaner, more precise final products.

Strong Compatibility & Cost-Effectiveness

Adapts to various casting processes and component sizes without requiring custom mold adjustments. Its low raw material and production costs also help reduce overall casting process expenses, delivering higher cost value for manufacturers.

Types of xinda Paper pouring tube

Pouring Straight Tube

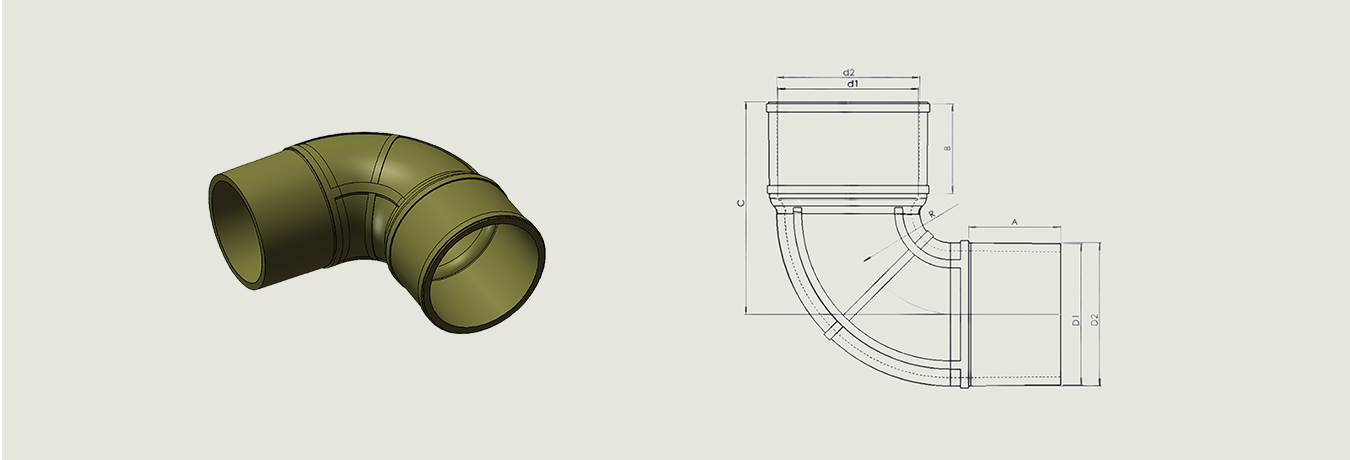

Pouring Elbow Tube

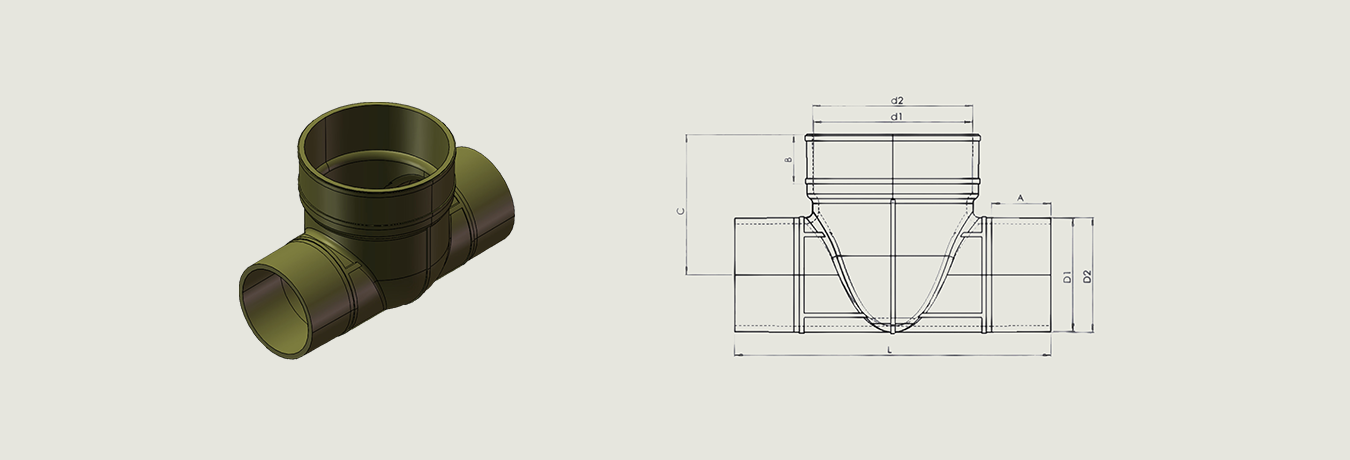

Pouring Tee Joint

| Type | Size(mm) | ||||||

| A | B | D1 | D2 | d1 | d2 | L | |

| ZYG-25Z | 22 | 22 | 29.5 | 30 | 30.5 | 31 | 310 |

| ZYG-30Z | 22 | 22 | 34.5 | 35 | 35.5 | 36 | 310 |

| ZYG-40Z | 25 | 25 | 40.5 | 41.5 | 44 | 45 | 303 |

| ZYG-50Z | 27 | 27 | 52.4 | 53 | 53.4 | 54 | 310 |

| ZYG-60Z | 40 | 40 | 60.5 | 61.5 | 64 | 65 | 303 |

| ZYG-70Z | 27 | 27 | 72.4 | 73 | 73.4 | 74 | 310 |

| ZYG-80Z | 30 | 30 | 80.5 | 81.5 | 84 | 85 | 300 |

| ZYG-100Z | 31 | 31 | 100.5 | 101.5 | 104 | 105 | 300 |

| Type | Size(mm) | |||||||

| A | B | D1 | D2 | d1 | d2 | C | R | |

| ZYG-25W | 22 | 22 | 29.5 | 30 | 30.5 | 31 | 52 | 25 |

| ZYG-30W | 22 | 22 | 34.5 | 35 | 35.5 | 36 | 52 | 30 |

| ZYG-40W | 30 | 30 | 40.5 | 41.5 | 44 | 45 | 80 | 46 |

| ZYG-50W | 27 | 27 | 52.4 | 53 | 53.4 | 54 | 65 | 50 |

| ZYG-60W | 30 | 30 | 60.5 | 61.5 | 64 | 65 | 80 | 57 |

| ZYG-70W | 27 | 27 | 72.4 | 73 | 73.4 | 74 | 84 | 60 |

| ZYG-80W | 30 | 30 | 80.5 | 81.5 | 84 | 85 | 95 | 67 |

| Type | Size(mm) | |||||||

| A | B | D1 | D2 | d1 | d2 | C | L | |

| ZYG-30/30S | 22 | 27 | 34.5 | 35 | 34.5 | 35 | 52 | 112 |

| ZYG-50/50S | 22 | 27 | 53.4 | 54 | 53.4 | 54 | 52 | 112 |

| ZYG-50/30S | 22 | 27 | 34.5 | 35 | 53.4 | 54 | 52 | 112 |

| ZYG-70/50S | 27 | 27 | 52.4 | 53 | 73.4 | 74 | 84 | 145 |