Phenolic Urethane No-Bake Resin

Ⅰ. Suitable for producing cast steel, cast iron, and non-ferrous metal castings, no-bake phenolic urethane resins offer broad application versatility.

Ⅱ. With high reactivity and fast curing speed, phenolic urethane resin for casting contain low levels of harmful elements such as sulfur and phosphorus, resulting in minimal contamination of molten metal.

Ⅲ. Featuring low levels of free formaldehyde, these resins release fewer harmful substances, making them more environmentally friendly.

Packaging: 1000kg/ plastic drum

Shelf Life: 12 months

Production Cycle: 7-10 days

Supporting Hardener: NP series hardener

- Information

Phenolic Urethane No-Bake Resin

Self-hardening phenolic urethane resin is specially designed to meet the demands of efficient and large-scale production on self-hardening sand molding lines. It is suitable for casting steel, iron, and non-ferrous metals, offering excellent adaptability across various foundry applications.

This binder system consists of three components:

Component I: Benzyl ether phenolic resin solution

Component II: Polyisocyanate solution

Component III: Catalyst

The curing time of this fast self-hardening phenolic urethane resin system is adjustable between 30 seconds and 2 hours, providing great flexibility for different molding requirements. The usable working time of the sand can reach up to 75% of the demolding time, allowing for efficient production scheduling and better control over the molding process.

In addition, the phenolic urethane resin for casting sand exhibits excellent flowability, making it ideal for both small batch operations and large-scale, continuous casting production. This ensures consistent quality and productivity across a wide range of casting scenarios.

Features

• High strength enables reduced phenolic urethane resin for casting usage without compromising casting performance.

• Good environmental performance help no-bake phenolic urethane resins improve working conditions at the production site.

• The excellent regeneration properties of phenolic urethane resin for casting enhance the reuse rate of reclaimed sand.

• Self-hardening phenolic urethane resin can effectively address casting cracks and structural defects, ensuring higher casting quality.

No-bake phenolic urethane resins

Parameters of Phenolic Urethane No-Bake Resin:

| Resin Component | Apppreance | Density (20℃) g/cm³ | Viscosity (20℃) ≤mPa.s | Free Formaldehyde | Shelf Life (Months) |

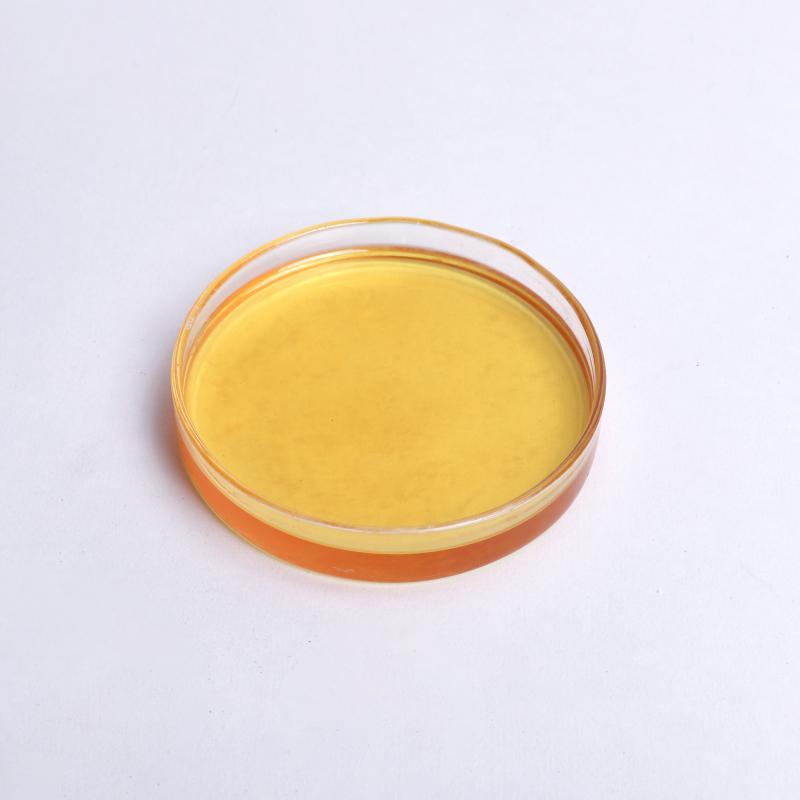

| Composition I | Yellow-green Clear Liquid | 1.02-1.12 | ≤300 | ≤0.3 | 6 |

| Composition II | Dark Red Clear Liquid | 1.10-1.20 | ≤100 | - | 6 |

| Resin Model | Characteristics | Application Area |

| NP-101HB/NP_102HB | Low Odor And High Activity | Casting Iron, Casting Steel |

| ZF-6060/ZF-6040 | Low VOC Excellent Comprehensive Performance | Casting Iron, Casting Steel |

| NP-301/NP-302L | High Intensity, High Wave Dispersion | Non-ferrous Alloy |

| Catalyst Model | Density (20℃) g/cm³ | Viscosity (20℃) ≤ mPa.s | Supporting Products | Temperature Range (℃) |

| NE 103A | ≤10 | 1.00-1.10 | NP 100 Series Resins | ≤15 |

| NP-103 | ≤10 | 1.00-1.10 | NP 100 Series Resins | 15-25 |

| NP-103E | ≤10 | 0.90-1.00 | NP 100 Series Resins | ≥25 |

| 7F-3750 | ≤10 | 0.90-1.00 | ZF series resin | ≤0 |

| ZF-3695 | ≤10 | 0.90-1.00 | ZF series resin | 0-25 |

| ZF-3650 | ≤10 | 0.90-1.00 | ZF series resin | 25-40 |

| ZF-3620 | ≤10 | 0.90-1.00 | ZF series resin | ≥40 |

| ND-303 | ≤10 | 1.05-1.15 | NP300 series resin | ≤20 |

FAQ:

Q: What is your typical production and delivery time?

A: Our standard production time is 7–10 days, or 5–7 days for urgent orders.

Q: How do we confirm the product quality after we place an order?

A: We conduct raw material testing before production and provide a detailed quality inspection report using high-precision instruments before shipment.

Q: What if there is a quality issue after no-bake phenolic urethane resins delivery?

A: Our professional technical team will provide support both during production and after delivery to resolve any quality concerns.