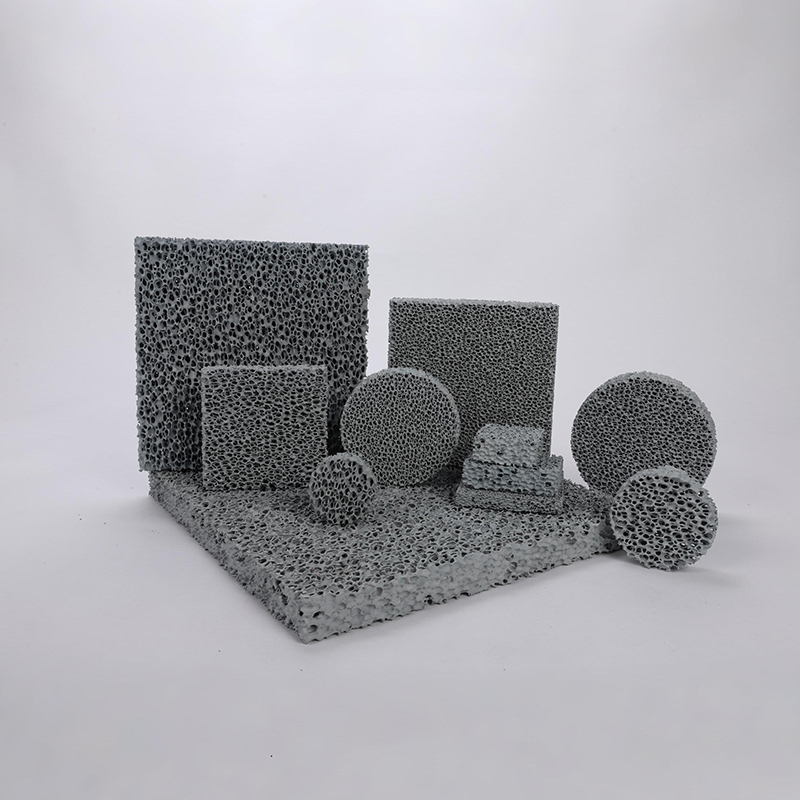

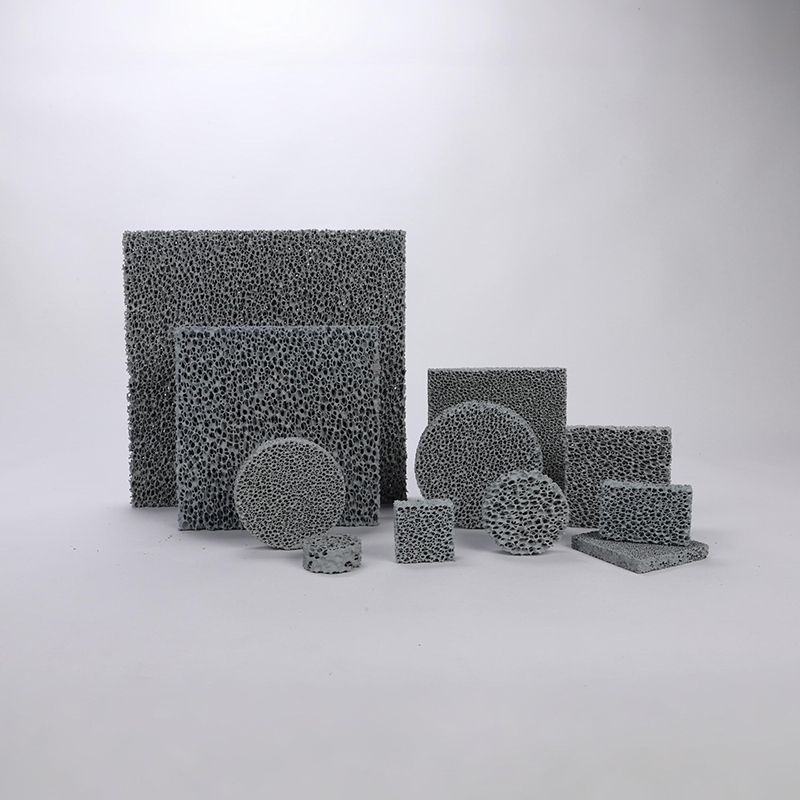

Silicon Carbide Foam Ceramic Filter

Ⅰ. In casting, silicon carbide ceramic foam filters effectively remove impurities and gases from molten metal.

Ⅱ. For cleaner structures and better durability, silicon carbide ceramic filters purify molten metals in various parts.

Ⅲ. In ductile iron, gray iron, and non-ferrous alloy casting, ceramic foam filters are used to filter molten metal.

Pore Density: 10-100ppi

Operating temperature: ≤1560℃

Application Scope: cast iron

Customized service provided: covered-edge, multiple shapes

- Information

Silicon Carbide Ceramic Foam Filters

Used in foundries to process gray cast iron, ductile iron, bronze, and other cast iron and non-ferrous alloys, Sic ceramic foam filter serves as a modern filtration solution. The silicon carbide ceramic foam filter we produce features high porosity and light weight. By effectively improving casting quality, Silicon carbide ceramic filter helps reduce scrap rates and enhances overall profitability.

Features

• With high strength and minimal slag buildup under both ambient and high-temperature conditions.

• Thanks to a stable and mature production process, our sic ceramic foam filter is ideal for mass production, offering consistent quality, excellent fire resistance, and strong thermal shock resistance.

• As part of advanced cutting technology, our sic ceramic foam filter features precise size control, full slurry coverage, and ensures residue-free filtration and maintains surface integrity of the casting.

Applications

For demanding automotive components, these ceramic foam filters ensure cleaner, lighter and stronger engine blocks. In addition, silicon carbide ceramic filters also help in the manufacturing of transmission housings and aircraft structures in the aerospace industry.

• Hydraulic components and pumps and valves: For hydraulic components and pumps and valves, cleaner castings are essential for high-pressure operation.

• Wind turbines and machine tools: Wind turbines and machine tools require durability and precision. This silicon carbide ceramic filter filtration ultimately contributes to the reliable and efficient operation of wind power generation and high-precision machining.

Parameters of Sic Ceramic Foam Filter

| Material | Silicon Carbide |

| Color | Grey Black |

| Pore Density | 10-40PPI |

| Porosit | ≥80% |

| Operating Temperature | ≤1450℃ |

| Compression Strength | ≥1.2Mpa |

| Application | Ductile iron Gray iron |

Dimensions of Sic Ceramic Foam Filter

| Square | 30*50*22 | 40*40*22 | 50*50*22 | 75*50*22 | 100*50*22 | 75*75*22 | 100*75*22 |

| 100*100*22 | 150*100*22 | 150*150*40 | 300*150*40 | 125*125*30 | 120*120*25 | ||

| Round | Φ40*15 | Φ50*22 | Φ60*22 | Φ70*22 | Φ80*22 | Φ90*22 | Φ100*22 |

| Φ125*25 | Φ150*30 | Φ200*40 |

About Us:

Our company is the core partner of Shengquan Group's overseas business. As a leading supplier of casting materials, we invest heavily in R&D talents and advanced equipment. With global standard quality and environmental protection technology, our products are widely used in traditional large-scale precision casting industries such as automotive parts and aerospace. We have a large production base in Shandong, which can provide stable and flexible one-stop services to global customers. We look forward to your inquiries and cooperation.