New Eco-Friendly High-Strength Cold Box Resin: Applications & Advantages

2026-01-27 09:28Xinda recently launched a new environmentally friendly high-strength cold box resin, an inorganic solution of organic resin, specifically by adding inorganic esters to one component, thus reducing the amount of organic solvents used.

This cold box resin utilizes a new organic-inorganic integrated technology, based on ecological and environmental protection principles and combined with a unique production process. It not only significantly reduces emissions of various harmful substances and has a low free formaldehyde content, but also possesses ultra-high moisture resistance, extending the storage time of sand molds. Furthermore, it exhibits excellent high-temperature performance, effectively improving the surface quality of castings.

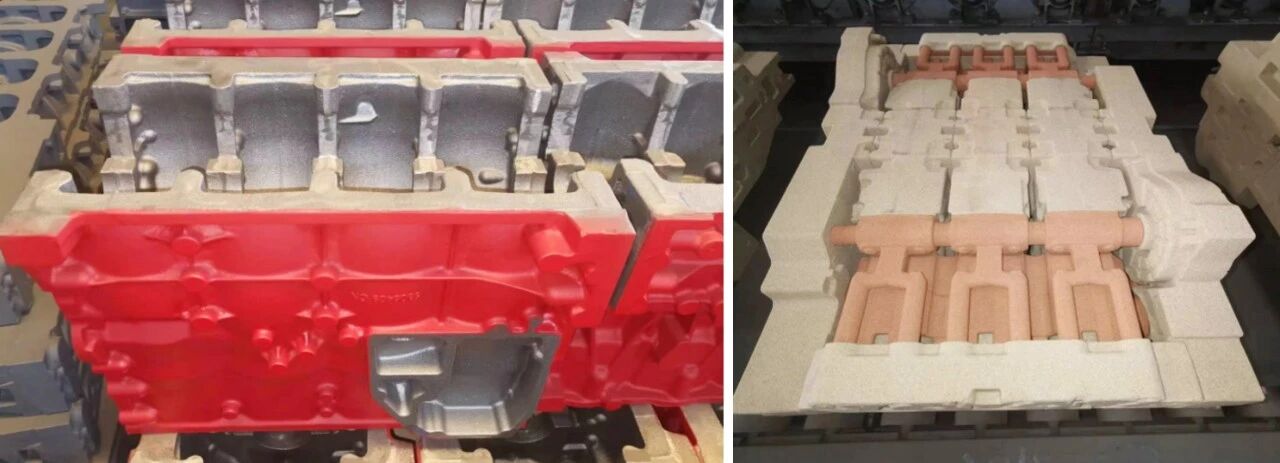

Xinda's cold box resin has already been successfully applied in several foundries, demonstrating its unique advantages. It is widely used in various automotive parts such as brake discs, engine blocks, cylinder heads, turbochargers, axles, flywheel housings, and wheel hubs, as well as various ferrous castings such as cast pipes. The addition of inorganic components increases the oxygen content in the resin system, appropriately reducing the reducing atmosphere during the casting process and lowering the risk of carbon defects, particularly noticeable in brake disc products.

1. Brake Disc

Material: HT250

Equipment: 25L cold box core-making machine

Resin addition: 1.2~1.6%, no coating, resin ratio 55:45 or 50:50

2. Four-cylinder block

Material: HT250, water-based coating, surface-drying furnace drying

Resin addition: 1.2~1.4%, 50:50

3. Wheel hub

Material: ductile iron 450

Equipment: 40L cold box core-making machine

Resin addition: 1.2%~1.6%, 50:50

In the future, Xinda will continue to deepen its technological innovation and product upgrades in the casting materials field, providing high-quality products that better meet the industry's needs for green and efficient development, empowering casting enterprises to improve quality and reduce consumption, and promote green production, working hand in hand with industry partners to build a new pattern of high-quality development for the casting industry.