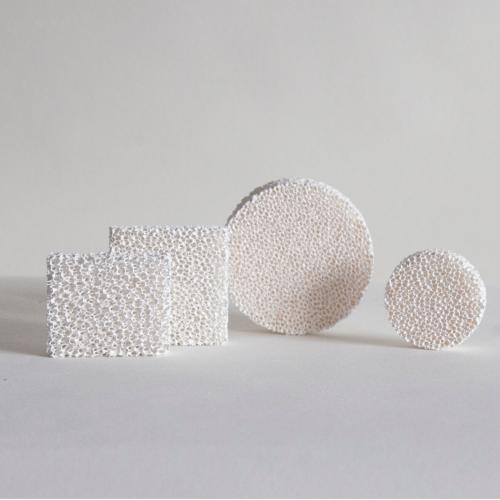

Alumina Foam Ceramic Filter

Ⅰ. Featuring precise dimensional tolerances and a refined microstructure, the alumina foam ceramic filter offers stable chemical properties.

Ⅱ. High filtration efficiency is a key feature of the aluminium ceramic foam filter mesh.

Ⅲ. Known for its excellent mechanical strength, the aluminium oxide foam ceramic filter also offers outstanding corrosion and thermal shock resistance.

Pore Density: 10-30ppi

Operating Temperature: ≤1300℃

Application Scope: cast aluminium

Customized Service Provided: covered-edge, multiple shapes

- Information

Aluminium Oxide Foam Ceramic Filter

Any project involving aluminum casting depends on the quality of the molten metal. Inclusions, contaminants and trapped gases can all seriously compromise the integrity, functionality and appearance of the final product. Ceramic foam filter for aluminum, sometimes called cast ceramic filter or aluminum casting filter, is a reliable and effective way to produce cleaner aluminum castings. Ceramic foam filter mesh has a wide range of porosity, measured in pores per inch (PPI). Aluminium oxide foam ceramic filter with higher PPI provide finer filtration, while lower PPI variants allow faster metal flow.

Advantages

• Beveled edges and compressible gaskets: Al2O3 ceramic foam filter compressible gasket and beveled edge design, by forming a tight seal inside the filter box, efficient filtration and reduced leakage.

• Higher casting quality: Filter Al2O3 foam for foundry by removing impurities and trapped gases achieving mechanical properties and smooth surface finish of the final casting.

• Improved yield: Filter Al2O3 foam for foundry can reduce casting defects, Al2O3 ceramic foam filter improve the yield of usable castings.

Applications

• Aluminum Profile Production: Filter Al2O3 foam for foundry ensures the structural integrity and smooth surface finish required for extrusions such as window frames and architectural profiles.

• Aluminum Alloy Casting: Filter Al2O3 foam for foundry ensures minimal casting defects and cleaner metal flow during the production of engine blocks, wheels and other complex parts.

Parameter of Al2O3 Ceramic Foam Filter:

Material | Aluminum ( Al2O3) |

| Color | White |

Pore Density | 10-40PPI |

Porosity | ≥80% |

| Operating Temperature | ≤1200℃ (please confirm) |

| Compression Strength | ≥1.2Mpa |

| Application | Aluminium Alloy, Copper Alloy |

Ceramic Foam Filter Mesh, Ceramic Foam Filter for Aluminum,Ceramic Foam Filter Mesh, Al2O3 Ceramic Foam FilterAl2O3 Ceramic Foam Filter

Dimensions of Aluminum Oxide Foam Ceramic Filter:

| Square | 50*50*15 | 60*60*15 | 70*70*20 | 75*50*22 | 75*75*20 |

| 100*50*20 | 100*75*20 | 100*100*22 | 150*100*22 | 150*150*25 | |

| Round | Φ40*15 | Φ50*15 | Φ60*15 | Φ70*20 | Φ80*20 |

| Φ90*20 | Φ100*22 | Φ125*22 | Φ150*25 | Φ200*25 |

Ceramic foam filter for aluminum

About Us

Liaoning Xinda Casting Technology Co., Ltd. the oversea business core partner of Shengquan Group. As an leading casting material supplier, we invest significantly in R&D talents and advanced equipment. With its global standard quality and environmentally-friendly technology, our products are widely applicated in traditional large and precision casting industries including automotive parts, aerospace, etc.