High-strength Riser Sleeve

I.Riser burns quickly, produces small amounts of gas, generates large amounts of heat, and has high compressive strength. Especially suitable for use on high-pressure molding lines with wet sand molds.

II.The high heating value and excellent insulation properties of this series of risers meet the high shrinkage efficiency requirements, with a shrinkage efficiency of up to 68%.

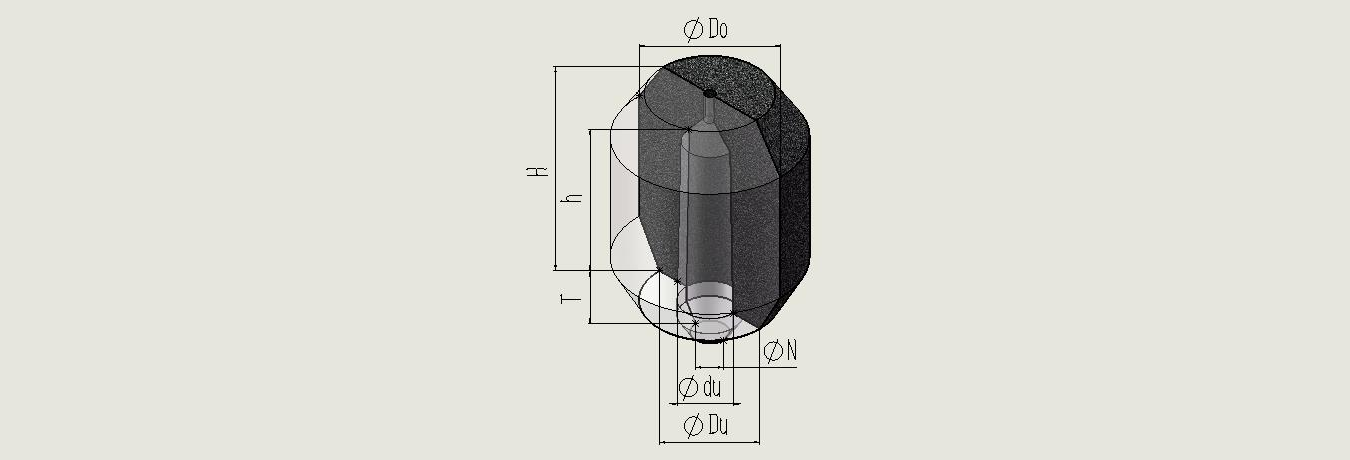

III.Anti conical structure, the upper wall thickness of the riser keeps the overheated metal away from the casting, and the thinner lower wall reduces the overheating of the neck metal.

- Information

High-strength Riser Sleeve

High-strength Riser Sleeve

| Specification | Modulus (cm) | Volume (cc) | Method of Application | Application field | Cautions |

Y8-36/17--770/30 | 1.3~4.2 | 37~772 | High-pressure molding | Green sand | The size of the metal breaker core will affect the feeding effect of the riser |

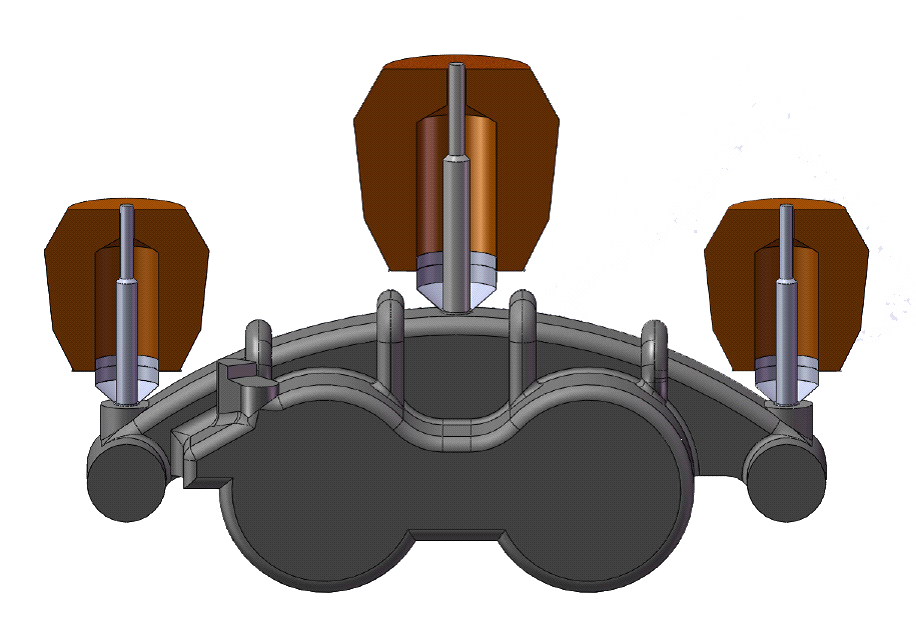

The feeding system has the following characteristics:

It can bear the pressure of the high-pressure molding line.

The mould sand is compacted excellently around the breaker core.

The exothermic material is completely separated from surface of castings.

Extremely small contract areas to the castings.

It is easy to be removed, and the fracture is in the same color of the casting.

It can be flexibly inserted.

It can effcetively solve the internal defect of isolated thermal center position in ductile iron castings.

| Specification | Modulus | Volume | Size(mm) | ||||||

| Du | du | Do | h | H | N | T | |||

| Y8-36/17 | 1.3 | 37 | 54 | 25 | 76 | 84 | 96 | 17 | 23 |

| Y8-56/19 | 1.4 | 56 | 60 | 32 | 87 | 84 | 97 | 19 | 20 |

| Y8-88/19 | 1.7 | 85 | 60 | 36 | 88 | 98 | 110 | 19 | 20 |

| Y8-105/19 | 1.7 | 103 | 66 | 40 | 87 | 100 | 107 | 19 | 20 |

| Y8-105/25 | 1.7 | 103 | 66 | 40 | 87 | 100 | 107 | 25 | 20 |

| Y8-121/19 | 1.9 | 105 | 66 | 40 | 104 | 98 | 116 | 19 | 20 |

| Y8-159/19 | 2.2 | 159 | 82 | 50 | 115 | 97 | 120 | 19 | 32 |

| Y8-191/19 | 2.5 | 195 | 90 | 50 | 133 | 116 | 140 | 19 | 32 |

| Y8-267/21 | 2.8 | 261 | 99 | 65 | 120 | 97 | 115 | 21 | 33.5 |

| Y8-267/30 | 2.8 | 261 | 99 | 65 | 120 | 97 | 115 | 30 | 33.5 |

| Y8-276/21 | 2.8 | 277 | 100 | 60 | 136 | 116 | 140 | 21 | 33.5 |

| Y8-283/21 | 3.0 | 321 | 99 | 65 | 115 | 116 | 140 | 21 | 33.5 |

| Y8-283/30 | 3.0 | 321 | 99 | 65 | 115 | 116 | 140 | 30 | 33.5 |

| Y8-339/21 | 3.2 | 336 | 99 | 65 | 133 | 121 | 140 | 21 | 33.5 |

| Y8-339/30 | 3.2 | 336 | 99 | 65 | 133 | 121 | 140 | 30 | 33.5 |

| Y8-339/40 | 3.2 | 336 | 99 | 65 | 133 | 121 | 140 | 40 | 33.5 |

| Y8-590/30 | 3.4 | 519 | 110 | 80 | 142 | 127 | 150 | 30 | 35 |

| Y8-590/40 | 3.4 | 519 | 110 | 80 | 142 | 127 | 150 | 40 | 35 |

| Y8-680/30 | 3.8 | 643 | 110 | 80 | 145 | 163 | 175 | 30 | 35 |

| Y8-770/30 | 4.2 | 772 | 110 | 80 | 205 | 180 | 205 | 30 | 35 |