How Casting Mold Release Agent Affects Sand Mold and Casting Quality?

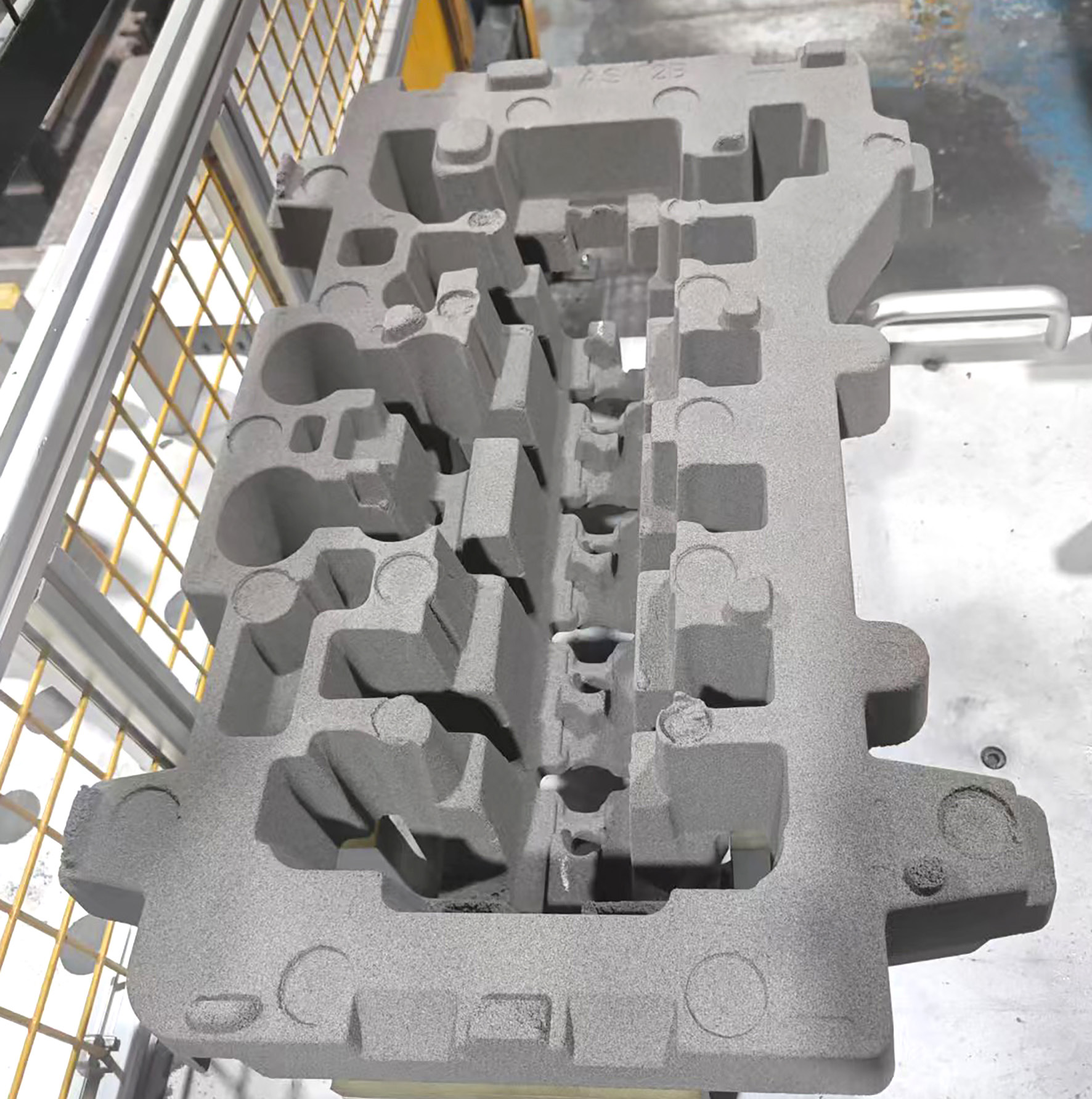

2026-02-09 14:00Foundry release agents are functional substances that act as a bridge between the mold and the sand mold. During sand mold making, the release agent forms a protective layer on the mold surface, preventing the sand mold from sticking and making demolding easier. This results in a clean, well-defined sand mold surface. It also protects the mold and core box, improving production efficiency. Xinda release agents, with their performance design closely aligned with actual production needs, are the preferred choice for many foundries. Through advanced R&D processes, they combine usability and practicality, ensuring the quality of both the sand mold and the casting from the outset.

Foundry release agents are crucial auxiliary materials in sand casting production. Their performance directly determines the integrity of the sand mold, the surface quality of the casting, and production efficiency, while also affecting the environmental protection and safety of the production process. Xinda release agents are compatible with different types of resins and sand molds of various materials, effectively solving common demolding problems in the industry and helping manufacturers improve production efficiency.

Chemical Stability: The Core Factor Ensuring Sand Mold Integrity and Effective Demolding

The chemical stability of the release agent is fundamental to its compatibility with casting processes and maintaining the integrity of the sand mold structure. It directly prevents demolding failure due to material reactions or high-temperature inactivation.

Resin Compatibility: When in contact with various resins used in sand molds, it will not undergo chemical reactions such as dissolution or abrasion, preventing release agent failure or binding with resin leading to sand adhesion and ensuring the integrity of the sand mold surface.

Temperature Resistance and Stress Resistance: It maintains chemical stability in the high-temperature environment of casting and can resist certain stresses. Even after multiple uses, it maintains a stable demolding effect, preventing sand mold damage due to high-temperature decomposition or failure, and reducing defects such as sand inclusions and sand adhesion in castings.

Physical Properties: Determining the Basic Applicability and Quality Stability of the Release Agent

The various physical properties of the release agent directly affect its ease of storage and use, as well as its compatibility with mold materials, and are crucial to ensuring consistent results with each use.

Appearance: Primarily brightly colored liquids or powdered solids, allowing workers to easily inspect the evenness of the coating and the quality of the release agent during brushing or spraying, preventing missed areas or thin coats that could lead to localized release difficulties.

pH Value: Needs to be controlled within a suitable range to ensure compatibility with sand mold and die materials. Excessive acidity or alkalinity can corrode the mold or damage its surface structure, extending mold life and maintaining mold integrity.

Active Ingredient Content: The active ingredient content must meet standards. Its content directly determines the release effect. Insufficient content leads to insufficient release force and sand adhesion, while excessive content easily leaves residue on the casting surface, affecting subsequent processing.

Quality Stability: This is one of the core indicators for evaluating the quality of a release agent, which can be tested through centrifugation. A good release agent, after high-speed centrifugation, will not separate or exhibit oil floating; all components will be uniformly mixed, maintaining stable performance during long-term storage and continuous use, and will not leave residue on the casting surface, ensuring casting surface quality.

Environmental Protection and Safety: Balancing Production Environment and Operational Feasibility

The environmental and safety performance of release agents not only affects worker health and compliance with production standards, but also indirectly impacts production efficiency and mold maintenance costs.

Low Harmfulness: Good release agents should have low volatility and low toxicity, reducing the release of harmful gases during production and minimizing the impact on worker health, while also meeting environmental emission standards.

Ease of Cleaning: Residues left after use should be easy to clean, avoiding the formation of difficult-to-remove deposits on mold and sand mold surfaces. This prevents residue buildup from affecting subsequent sand mold making and casting demolding, reducing mold cleaning time, improving production efficiency, and preventing secondary damage to molds, thus lowering mold maintenance costs.

Application Effect: Directly Determines Casting Yield and Production Costs

The ultimate value of a release agent lies in its actual performance; its performance directly affects the casting yield, surface quality, and overall production costs.

Highly Efficient Demolding: Enables easy demolding, reducing external impact on the sand mold during demolding, preventing mold breakage and sand loss, and preventing castings from sticking to the mold. This reduces defects such as sand inclusions, sand adhesion, and surface roughness in castings, improving casting yield.

Continuous Use: Can be used continuously; a single application can meet multiple demolding needs, reducing the amount of release agent used and the number of application steps, lowering raw material consumption and labor costs, while increasing production speed.

Xinda also provides customized formula optimization services based on the specific production needs of manufacturers, solving unique demolding problems. Coupled with comprehensive after-sales service, it provides full support for manufacturers' production throughout the process. Its professional quality has earned market recognition, helping customers improve their production competitiveness. Moreover, its products are reasonably priced, its service is efficient, and its experienced team can quickly respond to various usage issues, providing full support for manufacturers' production.